Edible Oil Refineries

Technology

Edible Oil Refinery

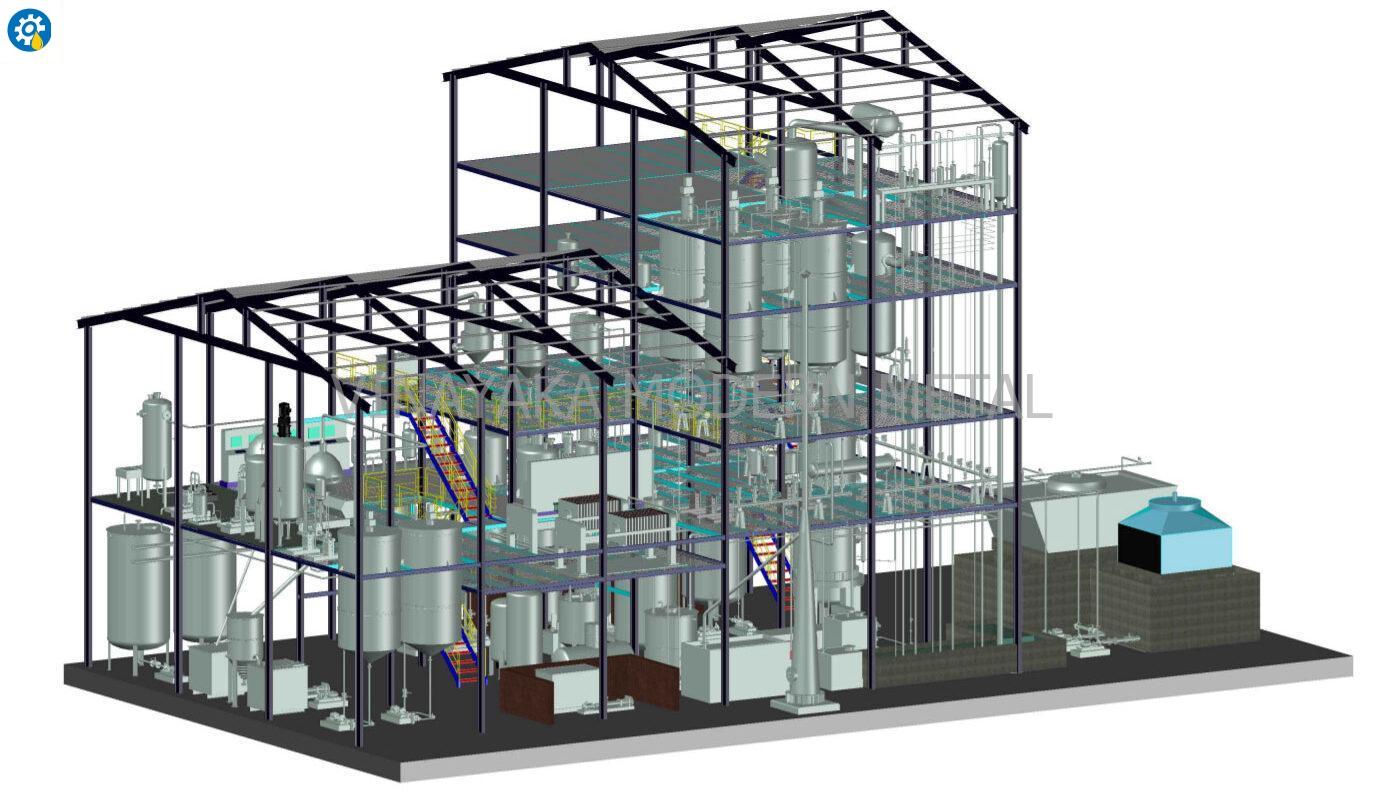

Edible Oil Refineries 3D Visualization

An Edible Oil Refineries functions as a processing facility wherein crude vegetable oils like soybean oil, palm oil, sunflower oil, and others are subjected to purification and refinement to yield top-grade edible oils suitable for consumption. This refining process comprises multiple stages aimed at eliminating impurities such as free fatty acids, phospholipids, pigments, and odors from the crude oil. The primary objective of the refinery process is to enhance the flavor, stability, and shelf life of the edible oils, all while ensuring they adhere to stringent safety and quality standards for human consumption.

With a focus on efficiency, quality, and sustainability, Vinprotech’s refinery plants are equipped with advanced technology and innovative solutions to ensure optimal performance and product quality. From small-scale units to large-scale industrial refineries, we provide customizable solutions tailored to the unique requirements of our clients, enabling them to produce high-quality refined edible oils efficiently and cost-effectively.

With a focus on efficiency, quality, and sustainability, Vinprotech’s refinery plants are equipped with advanced technology and innovative solutions to ensure optimal performance and product quality. From small-scale units to large-scale industrial refineries, we provide customizable solutions tailored to the unique requirements of our clients, enabling them to produce high-quality refined edible oils efficiently and cost-effectively.