Meal Conditioning and Bagging Section

Product & Services

Meal Conditioning and Bagging Section

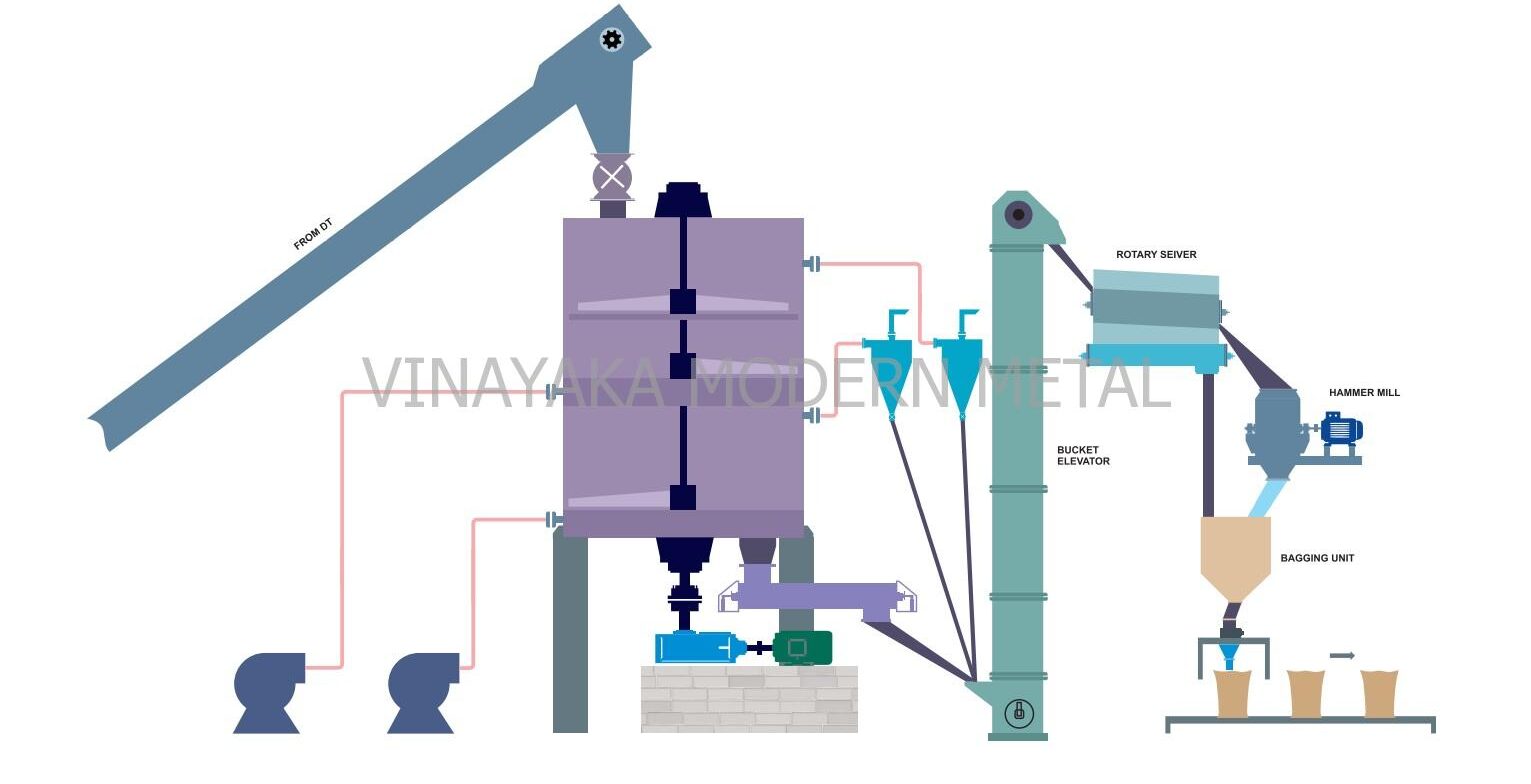

The extracted and desolventized meal is transferred to the meal conditioning area. Moisture is introduced, and the temperature of the de-oiled cake is lowered from 100°C to 45°C using a cooler. Finally, the end product is packed into small bags using bagging conveyors.